Technical

Knowledge

Using state-of-the-art technology during design and manufacturing is all good – and we use it throughout the process – but it can never replace the needed experience and deep knowledge about the materials concerned; what direction of the flat-rolled metal plate to cut, carrying capacity for each type of screw, how small a radius can be before properties are affected, precision and tolerances needed for a tight fit without creating too much friction, etc.

No chain is stronger than the weakest link.

The team of experienced technicians and engineers we have available, each with minimum 15 years in their field of work, is impressive and rock solid.

Marine conditions are tough on stuff – similar to nothing else. It is therefore of importance that suitable materials and processes are used when producing something that must stand this environment over time.

4S products pass all demanding exams.

Materials

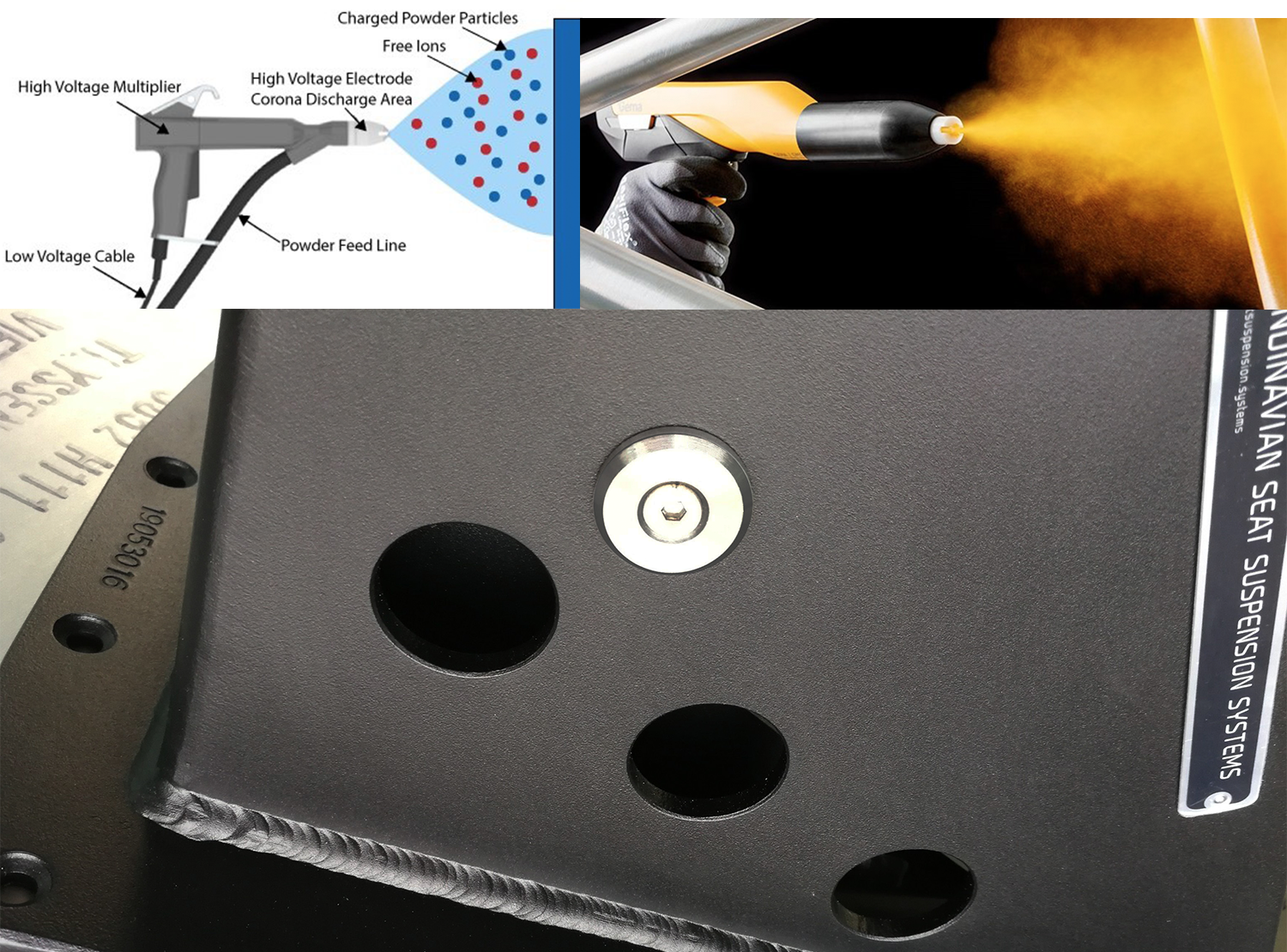

The 4S seat mounting products’ structures are made of 6061T6 and 5052h32 marine grade aluminium. Alloys used for salt-water sensitive applications where good corrosion resistance is needed. The electro powder-coated surface is AkzoNobel’s Interpon D2525. A ‘coastal architectual’ top-range product, UV-resistant, and suitable for use in a wide variety of conditions, environments and climates – from cold to hot, dry to humid.

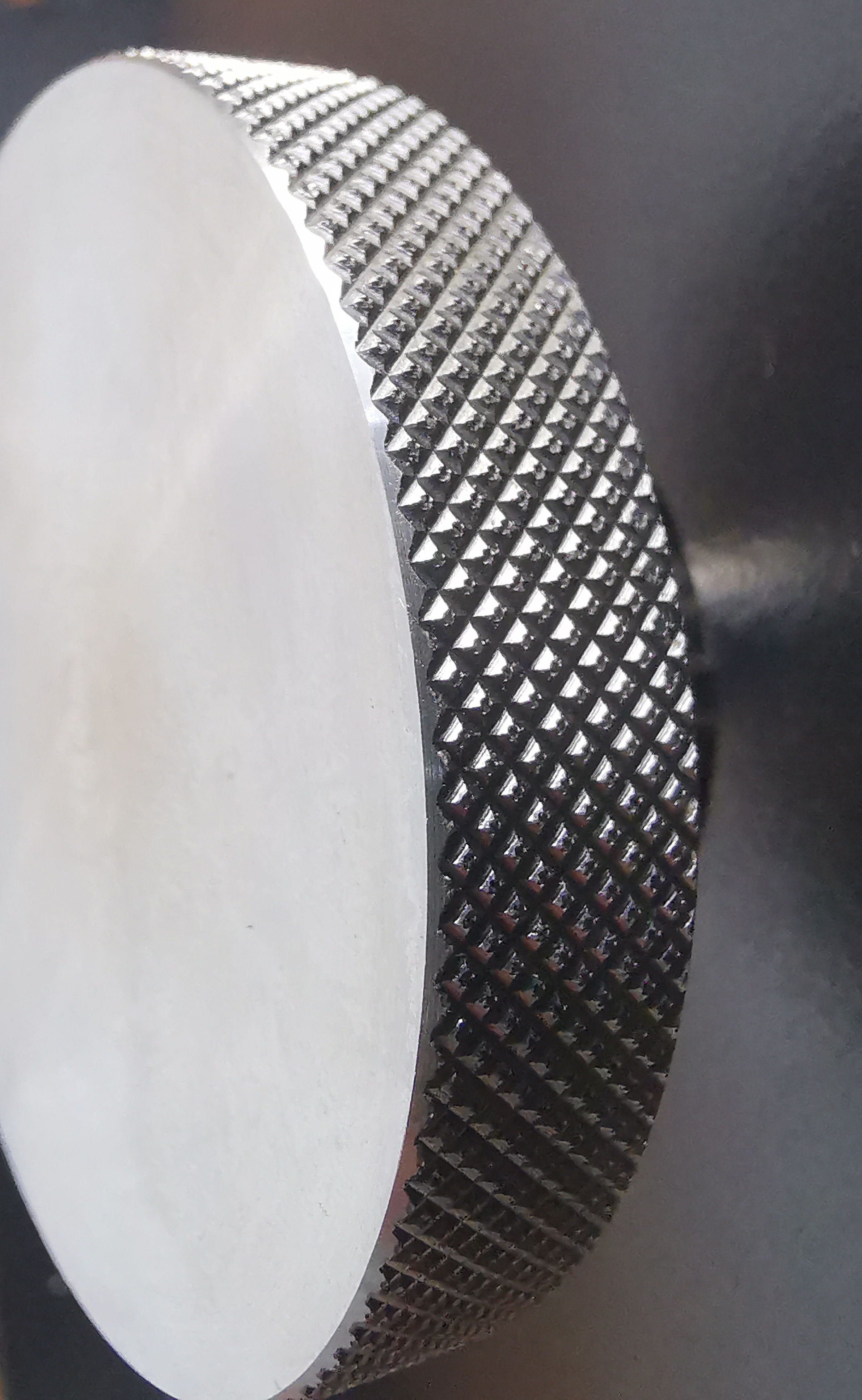

Components as adjustment wheels, levers, slides, rods, bolts, screws, nuts, and fasteners are all made of stainless steel AISI/SUS 316/316L.

Working plastic parts are made of POM (Polyoxymethylene) or 30% glass fibre reinforced Polyamid6.6.

Specs

Shock mitigation product range covers mounting heights (from under the seat) between 50mm/2” and 700mm/27,5”.

The standard deck plate is 225mm / 9” wide, and the mitigation base intended for jockey seats has a seat mounting plate only 190mm / 7,5” wide.

The mitigation bases are designed for leisure boats up to 50 knots.

Seats heavier than 15kg/33lb should not be mounted on any kind of vibrating marine installation that include moving parts.

The stiff, self-oscillating forces will rattle and wear out/widen the gaps that are necessary in moving parts.

Even though a person is much heavier than a seat, the human body consists of +50% water and is a shock mitigation and dampening force in itself – whereas a stiff and rigid mounting (chair) will just be an extension/elongation of the vibrating seat base, and by being so; multiply the wearing forces on the fasteners, bearings, bushings, etc.

Spring rates are infinitely adjustable between 60 and +130kg, and progressive in order to avoid “bottom out”.

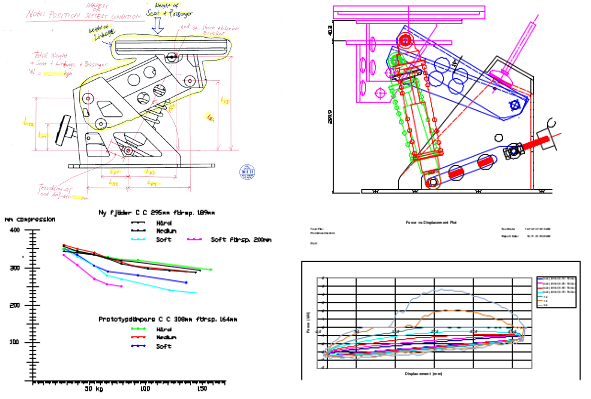

The shock absorber profile is developed together with both Kayaba and Öhlins, two of the world’s leading shock absorber researchers, – developers and –manufacturers.

The shock absorbers have passed endurance tests, simulating 500 hours of hard driving (+6G) per year, during more than 30 years usage.

4S Seat Mounting products meet the ABYC H-31 standards for highest type AO.